The Advantages of Buying from This Manufacturer

Are you searching for trench shoring boxes of high quality and inexpensive? Well we’ve the finest options for you seeing your needs. You can expect new trench boxes for sale which are immediately costed empowering one to save much of your money and time thereby functioning as an added advantage for you. Moreover, we providing inexpensive shipping charges and we have been adaptable to send the trench boxes anywhere regardless of your current place. Around, you’re assured of quality trench boxes which will last accordingly and guarantee you success in your building job. In addition , we make funding available for you therefore less difficulties as you purchase them

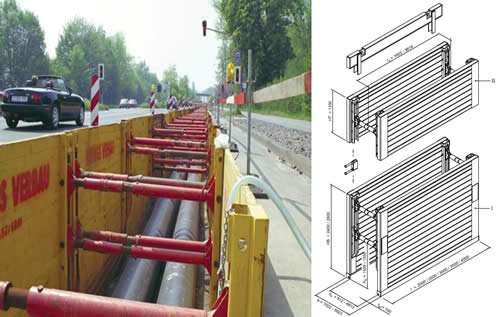

The Down-Low of What Trench Boxes Are

Trench boxes refer to developed structures which are made of metal that are changed to shield energy employees when performing their jobs while in a trench. Our firm constructs each box in distinct side walls to ensure that their thicknesses vary. This produces assortment for one to pick on because you’re not limited to your special type of thickness. These boxes are then held aside by using metal spreaders which are adaptable so you could interchange them when need arises depending on the breadth of the trench you’re working with. This metal shoring box is so significant and stresses substantially on the utility employees protection when in the trenches

We recognize that at occasions the need to have metal trench defend appears and so we ensure that this is provided in excellent moment to your use. We aim at understanding your entire needs because this really is crucial in terms of the trench type that you’re required to shore up. We thus make the metal protects accessible for you to avoid cases of inconveniences. After making a choice on the specs you need, we’re happy to supply them at the place that you’re within the time requirements you provide.

Deciding Upon Whether to Buy Aluminum or Steel Trench Boxes

In regards to choosing what trench shoring boxes to buy, it truly is critical to consider the type of task you’re functioning on in addition to the sum of building job demanded. Furthermore, you’re required to have a look at the time duration the project may simply take and the expense of the job. Keeping this in mind may enable you choose the best steel shoring method that will last efficiently basing in your needs. Like other building equipment, it is common for the trench boxes to expertise use and split and therefore as you make a pick on which one to purchase it’s important to retain considerations on them

However, some trenches may possibly have now been used at least once every so often in the appropriate way that they are still in good condition. This may be so if the trench box wasn’t used approximately or wasn’t uncovered to quite rough states and therefore contemplating this one in good condition also can be more affordable than purchasing a brand new one. Yet, selecting on one which will give inferior stuff as the outcome is so much deterring and s O in this instance a good idea is to pick on a fresh one which will provide quality outcomes for you

Conclusion

In terms of purchasing this http:trenchshoringboxes.com it’s vital that you be attentive to prevent selecting one that has lost shape and isn’t going to last perfectly. As you prepare to purchase one, you need to find out the sum of money you have in addition to the kind of building job that you’re having at hand. With this in mind, contemplating us to offer you with quality trench boxes may behave as an investment for you